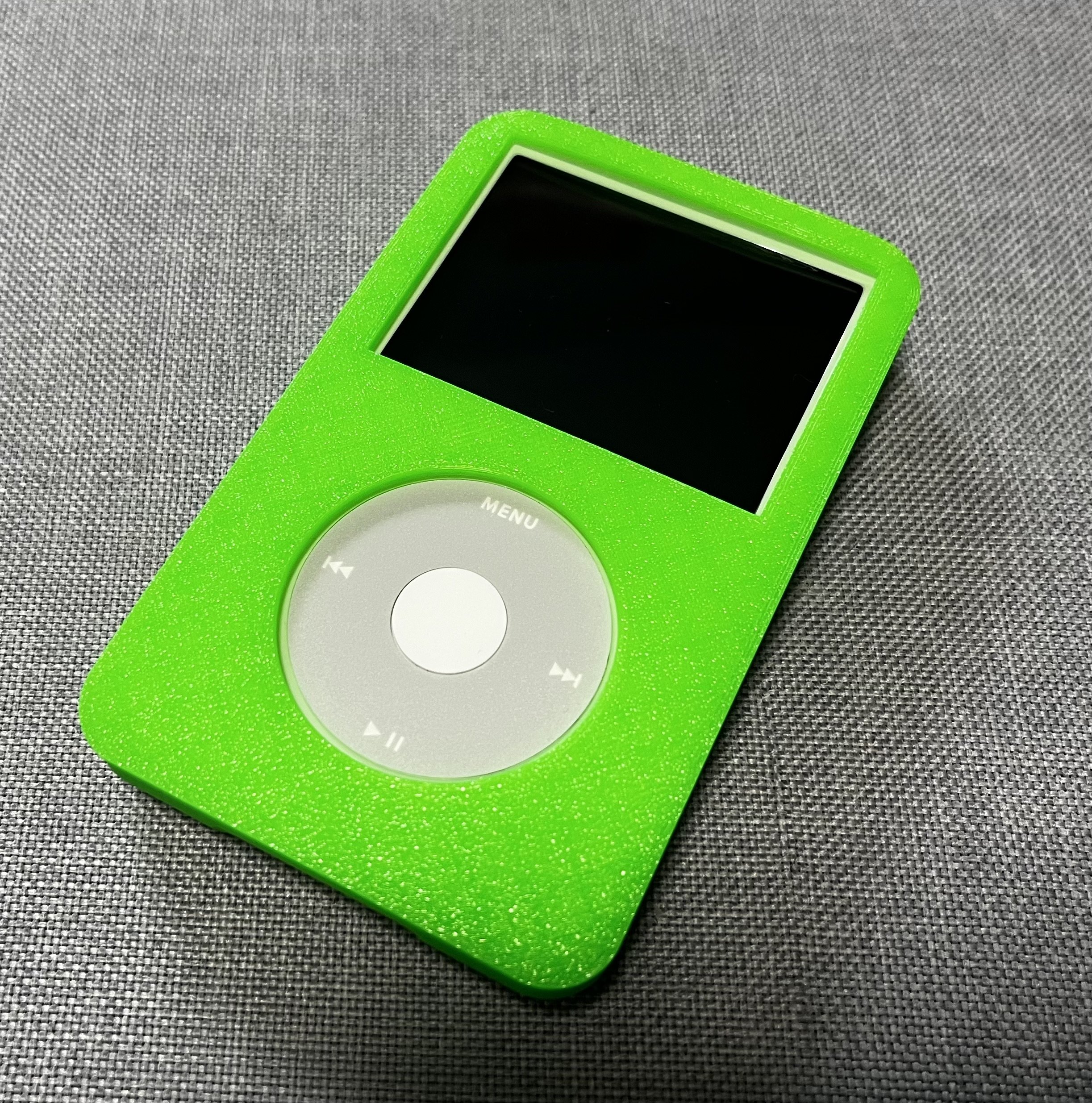

I thought it might be interesting for anyone planning to upgrade their standard Voxelab Aquila to see what I did to mine. Print quality increased much, even though there are printers that are even better (of course).

I got this one back when it was on sale at amazon for around 150€. I wasn’t planning on getting a 3D printer and had absolutely no idea what rabbit hole I am going to fall into. I just got a bonus at work at that time and thought „why not“. Since then I thought about upgrading to a better printer a few times, but as I became father two times in the last two years I always decided on saving the money and just go with some improvements for my Aquila. So over time it transformed into what you can see here.

I will try to list all of the upgrades, but I might forget some. So if you have any questions, feel free to ask.

Upgrades:

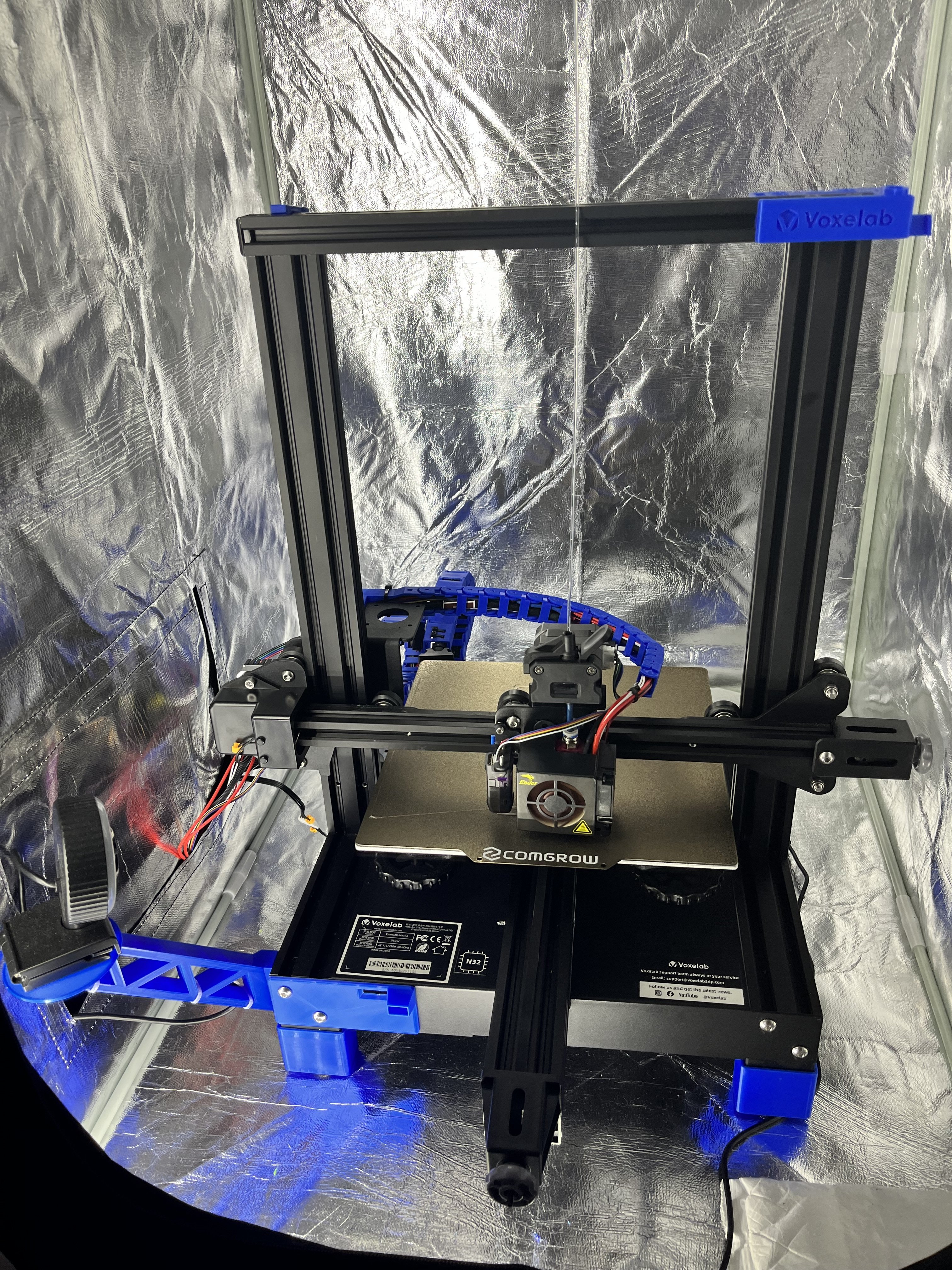

- DirectDrive

Creality Offiziell Sprite Direct Drive Extruder SE für Ender 3/Ender 3 V2/Ender 3 Pro/Ender 5/Ender 5 Pro/CR-10, Edelstahl Dual Gear Upgrade Ender 3 Extruder, Unterstützt die Meisten Hotend https://amzn.eu/d/1lhH7JU

-

Ender 3 Pully Backplate with official Ender 3 Hotend Kit (got this one as I had some serious trouble with my Hotend not extruding anymore as filament got stuck. Turned out I have to leave the enclosure open for PLA… But I just leave it as it is now)

-

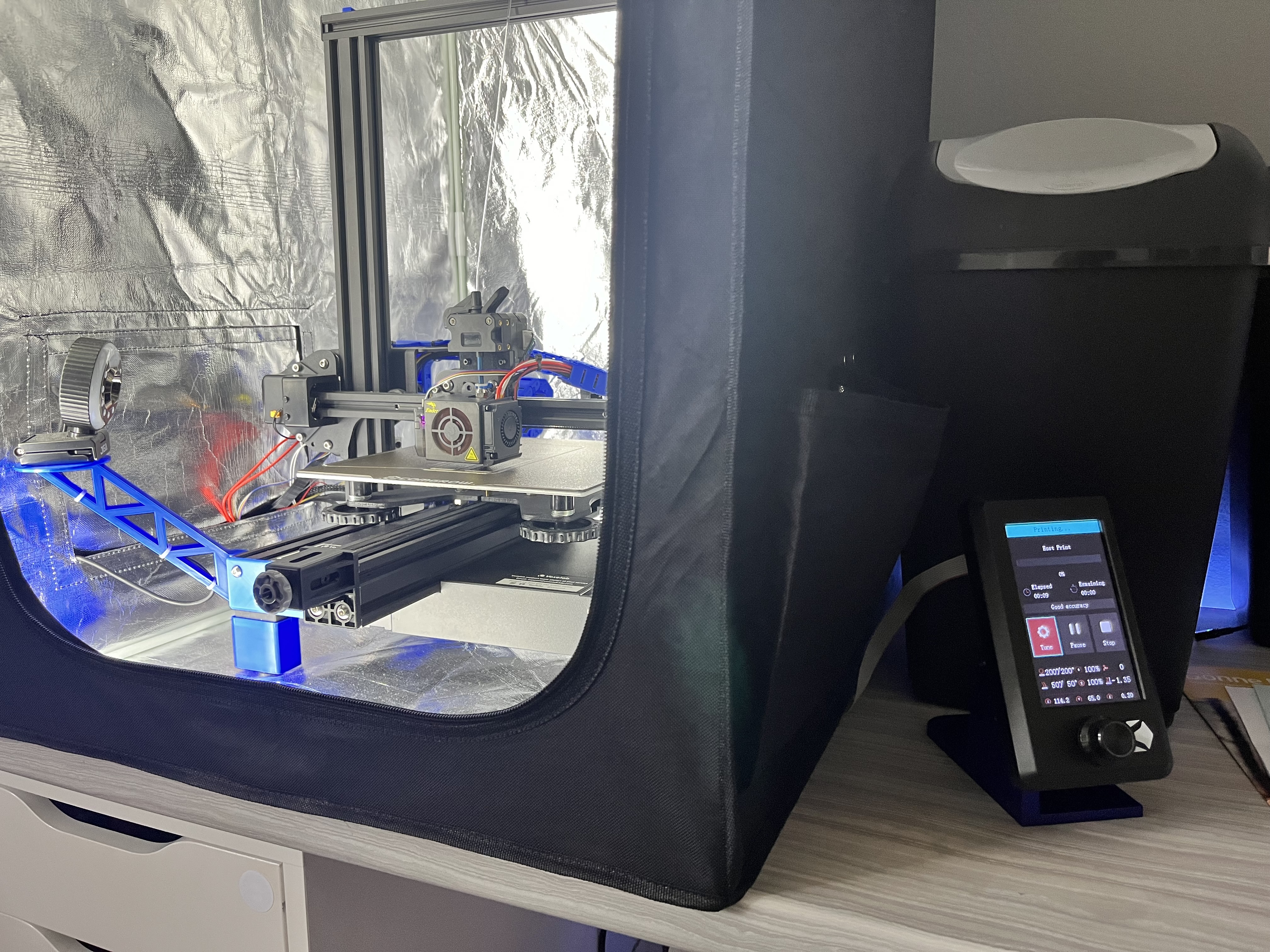

Enclosure

SUNLU 3D-Drucker-Gehäuse, konstante 3D-Drucktemperatur für ABS 3D-Drucker-Filament, Ender 3/3 PRO 3D-Drucker-Gehäuse, bietet viel Platz, feuerfest, Größe 650 * 550 * 750mm https://amzn.eu/d/eHXB8Kb

- Filament Dryer as direct Feed

eSUN Trockenbox für 3D Drucker Filament, eBOX Lite 3D Drucker Hält das Filament Trockenbox, Staubdicht und Feuchtigkeitsdicht, Kompatibel mit 1.75mm, 2.85mm, 3.00mm Filament https://amzn.eu/d/idSAFa2

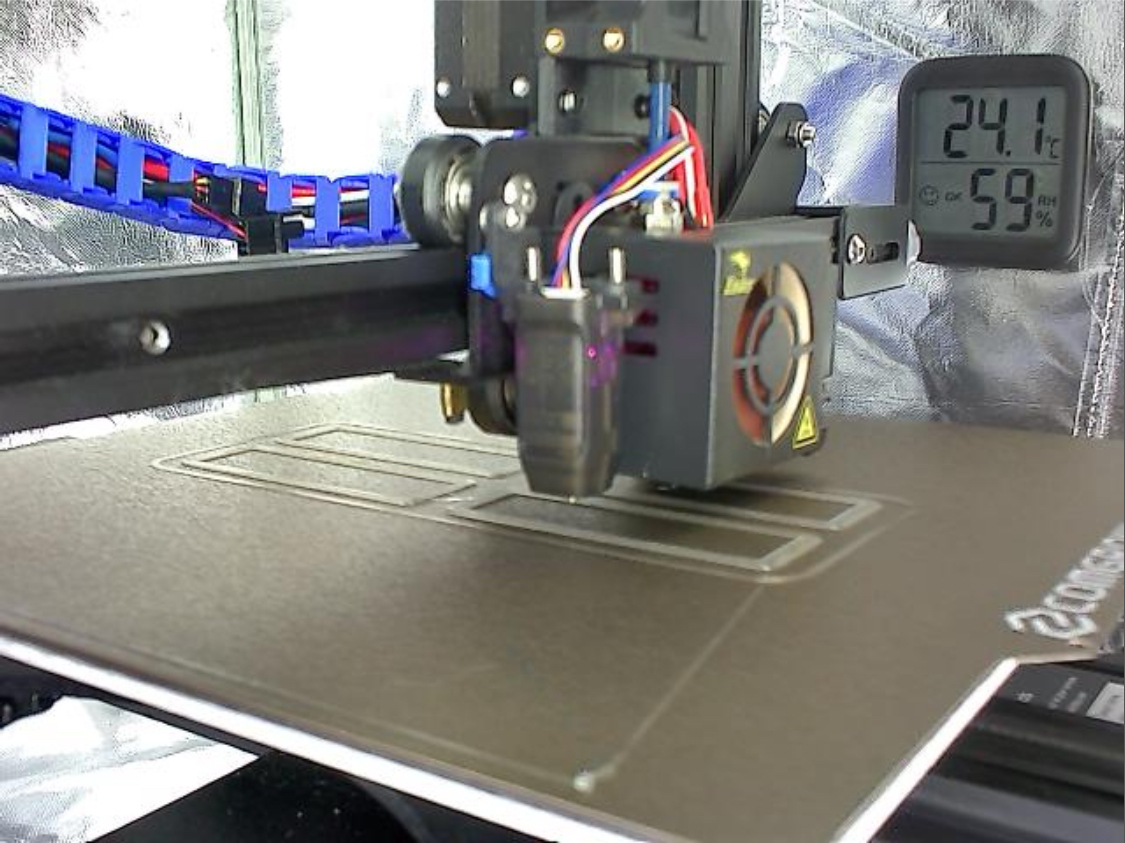

- PEI printed

COMGROW PEI Sheet 235x235mm, Pei Druckplatte for Creality Ender 3 Pro/Ender 3 V2/Ender 3 S1/Ender 3 S1 Pro/Ender 3 Neo/Ender 3 V2 Neo/Voxelab Aquila 3D Drucker https://amzn.eu/d/0GWosXC

- Placed the display outside the enclosure using an enlargement cable

POPESQ® 1 STK. x IDC Verlängerungskabel 10 polig 50cm 2.54mm Verbinder / 1 pcs. x IDC Extension Cable 10 Way 50cm 2.54mm Connector #A1917 https://amzn.eu/d/iPmrouH

-

Placed MainBoard and PSU outside the enclosure using some printed parts to protect them (and myself because I tend to touch it accidentally)

-

Raspberry Pi 3B+ running Octoprint

-

Some cheap webcam to have an eye on my prints using Obico with Octoprint

-

Temperature and Humidity Sensor I placed inside the enclosure to have an eye on it over the webcam

-

3D Printed parts

Riser feet for better airflow (might be outdated because of the electronics now being placed outside the enclosure). Webcam Mount, cable chain, LCD mount, Filament Dryer shelf, MainBoard and PSU enclosures.

Here are some additional more detailed pictures:

The webcam view:

I am not happy with how the electronics are placed outside right now as it looks kinda improvised (what it is…), but I didn’t want to enlarge all of the cables. Maybe that’s work for future upgrade time.

So as I said, if there are questions I am happy to try to answer as helpful as I can :)

Sorry for the late answer. It’s this one:

https://amzn.eu/d/04M6Ih6n