3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

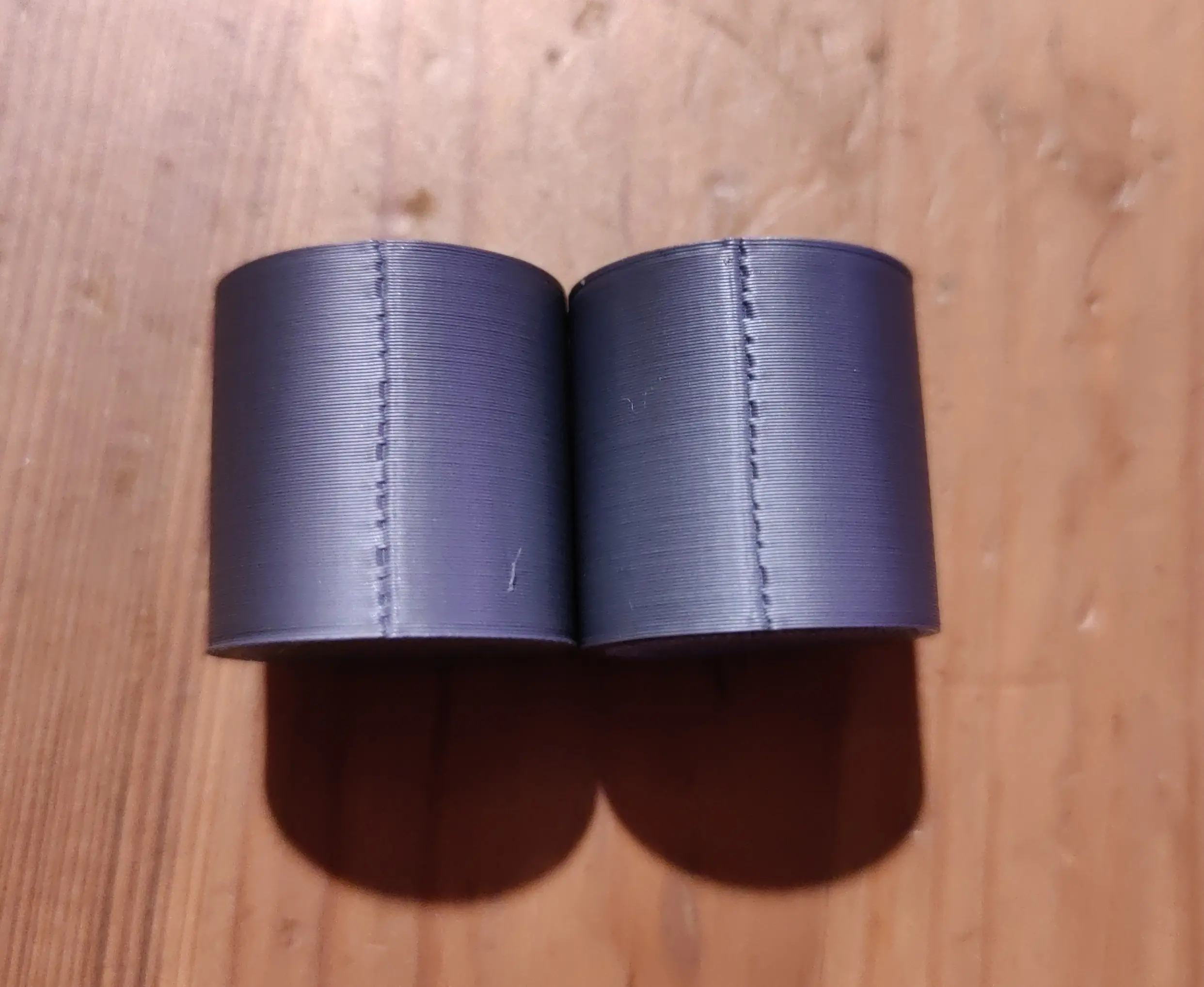

Disclaimer: I'm not into 3d printing. I'm just a wannabe with not enough time on my hands, so take this post with a bucket of salt. I have, on the other hand, worked a lot with automated machinery.

But if I were to make a guess, I would suspect some slack in either the X or Y direction, resulting in inaccuracy when the nozzle changes direction. This should in theory be less visible when the nozzle is not making sharp turns.

Are your belts tight? Any gears with poorly meshed teeth?

Also, are you able to turn the print (and the seam) 45 and 90 degrees? Do they show up just as ugly? If not, the issue is mechanically limited to one axis.

Actually yeah, you might be on to something there. OP could try adjusting belt tension.

If you do end up adjusting belt tension though, make sure to recalibrate your e-steps after.

It's worth a look but I really suspect PA to be the culprit here. The differences between the layers are probably explained by the feed rate after or before the turn due to different path planning.

No, that issue would show a problem with layer stacking as well, which is not the problem here.