Fuck it 🤷🏻♀️ my uncle dropped 8k on a 3D printer post-divorce, and if working on a lil art and engineering makes him feel better I can support that.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

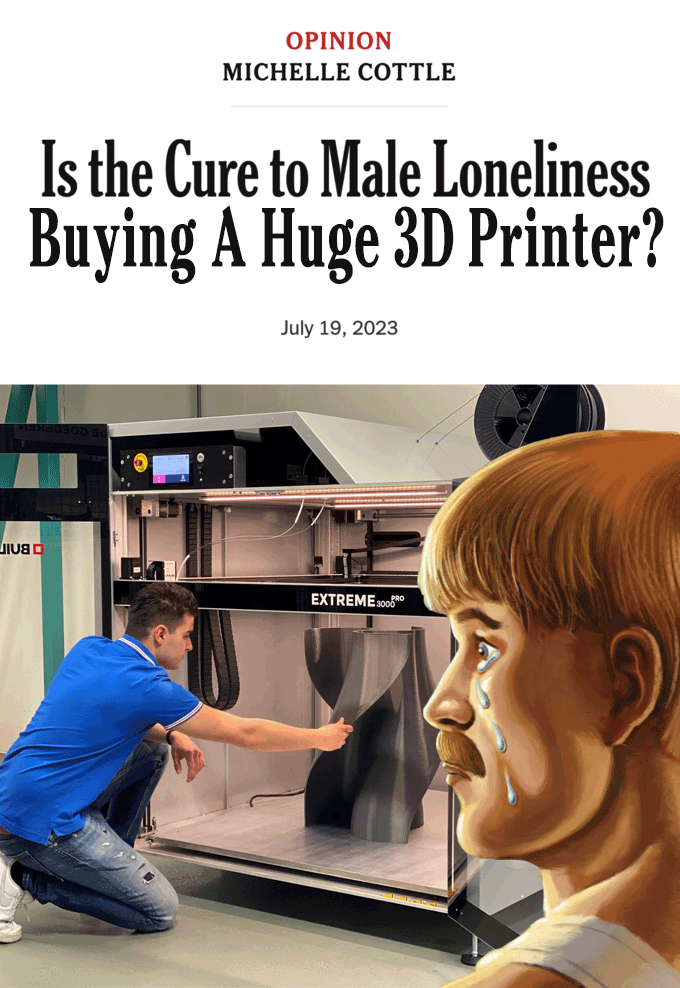

In case anyone is curious, the printer in the picture is 1100x1100x820 mm and costs $50k USD.

https://builder3dprinters.com/us/product/builder-extreme-3000-pro/

curious machine. I'm surprised to see such mediocre specs with that price tag.

claims to be industrial yet uses 1.75mm hot end and can't print any industrial grade materials

There's a reason you don't often see machines over 300x300x400. At that point it gets hard to keep tolerances tight, requiring manufacturing changes or else you end up with printing artifacts.

This thing prints at 300mm/s at 1100x1100x820 and it's manufactured in a first world nation at low volumes.

It's hard to see, but I think they made the gantry (the whole Z platform, I mean) out of two plates of aluminum. They didn't bolt i beams together, it's just two massive plates with holes cut into them. That's the sort of engineering they did to get this thing to work at that size, with that speed.

Doing that is expensive.

The support is awesome.

The mixing nozzle/extruder is one of the better ones.

What you call medicore specs are decent parts. They use ball bearings fan, Misumi stepper, etc. paired with decent workmanship like strain relieving the cables.

~~What could be cheaper are the nozzle replacements at 70€ each.~~ Still not the worst out there in terms of nozzle pricing (e.g.150€ for a brass nozzle + heater ... [different company]).

Edit: It was 70€ for 2 builder nozzles or 175€ for 6.

I built a 36" x 18" x 18" by welding a Prusa style aluminum frame up from scrap aluminum plate, and running the bed on 8mm rods and bearings. Dual Volcano 1.2mm hotend, it prints nearly as fast as that. It has about a dozen 110V heater pods mounted to the aluminum/glass bed. I've printed some big things on that since I built it about 8 years ago.

I might be $500 into it.

3d printers are the new classic car that needs a little bit of work.

Ugh, I have both and now I question what that means about me.

slaps roof This baby has been going since the early '20s. We've been through a lot together, almost every part has been replaced, and it's still not reliable!

If you have one of the consumer metal printers and a consumer plastic printer, it means you can print your own car parts from aluminum, iron, or lower carbon steel pellets, and all the trim with the plastic printer.

Congratulations, you have a body shop, and an example car.

Getting ahold of the original specifications becomes the biggest challenge at that point, so that you can manufacture the parts within tolerance.

How does it get to the right temperatures??

What? The printer? They use metal pellets and AFAIK, you program the printer to heat an induction coil to melt the pellets.

I have a 3D printer, and a Suzuki Samurai. More than a few parts for the 35 year old Suzuki have been printed by me.

Why not both!? I've used one to make parts for the other.

How do you use a car to make parts for a printer?

I'll tell you what, using that points distributor on my Lulzbot has sped up printing considerably! Unfortunately the print nozzle connected to the 401 nailhead sure makes the Buick hard to start.

I have been making parts for my FIL’s 61 Ranchero. I have made almost every gasket, the heating couplers, and dash knobs.

I've made a few logos. One of them I used to make a stamping die that deformed some sheet metal. Worked shockingly well.

I've also made a simple phone mount and a lens for the glovebox. My ultimate plan is to make the housing for new headlights, but lack of time and wanting to scan rather than measure the sheetmetal opening has slowed me down on that project.

My AI girlfriend says she is in there waiting to get out

If some one wants to buy me one, I’ll be happy to report back,

Just outing myself here as female should someone wish to do a comparison study across genders.

Gotta do the study properly. Diverse pool, control groups. Relatively long periods…

I'm not lonely. I could be part of the control group.

it's a hard job, but it's for science, and you have to do science right.

so we really need every one in on this.

Image Transcription:

An Opinion article by Michelle Cottle reading "Is the Cure to Male Loneliness Buying A Huge 3D Printer?"

Below is a photo of a man using an Extreme 3000 Pro 3D printer with a drawing of a crying man standing to the side and watching him.

[I am a human, if I’ve made a mistake please let me know. Please consider providing alt-text for ease of use. Thank you. 💜]

Prove you are a human

I am a human, and I can verify this user is also a human.

Just last meal time we enjoyed stuffing foodstuffs into our primary face holes to acquire energy. Afterwards we used said face holes to communicate inanities to each other. We then ingested ethanol to impair our brain function and attempted to create more humans by mashing our ridiculous meat bodies together.

Checks out.

Somebody call Anthony Michael Hall, it's time to Weird Science our way to mental health!

I just got a huge CNC, will that work?

Depends on the number of axis.

anything below 7 doesn't count

We got a baller over here!

:swooon:

Depends on the soft jaw chuck

Is…to print sex dolls? Is that the goal? Building the girlfriend?

No, there is no goal only you'll be so busy calibrating and optimizing and upgrading the printer you won't have time to be lonely.

There is only printer.

fucking microplastics

And macroplastics

sounds good!

Nah, you dont need to print the whole woman.

Uh, question. What if you don't have a 3D printer, but need something 3D printed? I've asked around, and there are no 3D printers available in this area. Is there an online fabrication service you can use? I want to get a higher profile D-pad for my Switch Lite, to replace the crappy one Nintendo put in there by default. Unfortunately, there's limited size tolerance, and it seems that specific equipment is required.

Reddit had a community called something like 3dprintmything where you could post what you were looking for and get bids from folks who could get it to you. I dunno if we have anything like that here.

Already a reality here https://www.youtube.com/watch?v=P2iaMCmOrh4

Here is an alternative Piped link(s): https://piped.video/watch?v=P2iaMCmOrh4

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source, check me out at GitHub.