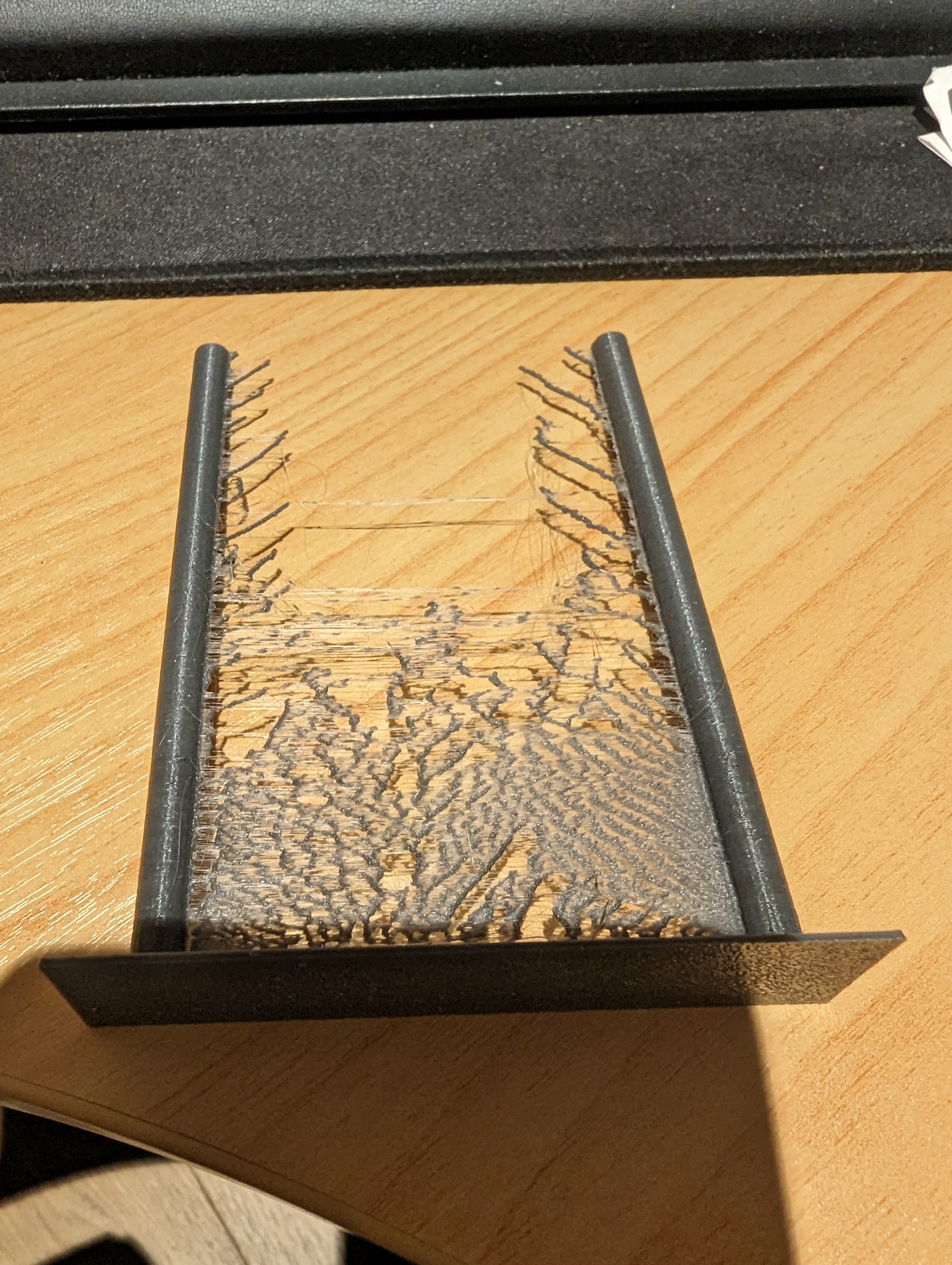

Turn off z-hop. When you use zhop the nozzle elevates and it cannot wipe itself. When zhop is off the nozzle wipes itself with the top layer. I know this might be a pre-sliced test but in real life scenario you can make the wall first and the infill last so any minor stringing remaining will be inside the object. As well the obligatory filament drying.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

This is a delta printer, z-hop should be much faster than a traditional bed-slinger and leave much less stringing assuming the z speed is set appropriately. Personally, I run z-hop enabled 95% of the time unless I know the objects don’t need it.

Thanks for your reply, I will give that a go.

After posting I thought to try a different brand of filament. It's currently printing, so we'll see how it goes.

Yeah both new filament and no zhop might help. Also check travel speed, use 100-150 or more to reduce stringing. You said you want higher flow, but lowering temp can help a lot

Yeah it was rubbish filament. Switched it out for some esun PLA+ and got much better results. I've updated my post, but final settings are:

Pressure Advance - 0.4 Retraction - 3.5mm Retraction speed - 35mm/s

Very happy with the results!

To get the shitty filament running you can still go for fast travels, 300mm/s@15 to 20k should be fine.

Thanks. I'll try that.

I'd call that oozing more than stringing, but they're nearly the same issue. It's leaking out after retracting, still some in the hot zone. I'm struggling with it too. The best mitigation I've found is to lower temperature.

Yeah lower temps work, but I'm really trying to max out my flow rate so I want to run it as high as possible. Pressure advance really helps reduce ooze, and quality filament is obviously a must.

Its a balancing act so if you are only upping the temperature to get higher flow but not the speeds to use that higher flow then there will be some issues. Each filament also has different temperature and flow characteristics so just because the new filament works with the current settings doesn't mean the old filament was junk.

Hmm yes, good points. I'll have another go with the previous filament.

To be fair, I need to replace the extruder and get a high flow nozzle anyway, which I think will make more difference to the flow rate than running hot.

Could be moisture in the filament contributing.

In the end it was crap quality filament.

I keep my spools in a dehumidifier which I actually think is too dry. Some of the filament was brittle for the first 6" or so.

Here's the retraction calibration test I use http://retractioncalibration.com/

That site doesn't load for me. I have just been using a retraction tower and running the tuning function from the command line.

Honestly the first one looks cool and you should put it on display

Yeah, it's very pretty. Happy accident. :)

Ugh, I'm also having the problem. I'm using eSUN PLA+ in black and white. I've even dried them out 12+ hours and store them in a waterproof box with desiccant.

I'm at my wit's end trying to figure out why it's stringing so badly. None of my other rolls before these did it.

What temperature are you printing at? When I was using Marlin I ran mine at about 200, and could probably have gone even lower. I also tuned linear advance which made a big difference.

I have found that some esun spools weren't particularly dry when I got them. They sit in my dehumidifier which sits at about 20%, so they get dry eventually.

You can try coasting as well I think.