this post was submitted on 15 Oct 2023

1454 points (99.1% liked)

Woodworking

6155 readers

9 users here now

A handmade home for woodworkers and admirers of woodworkers. Our community icon is a planter box made by @Captain Aggravated, the winner of our summer '24 woodworking contest. Congratulations!

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

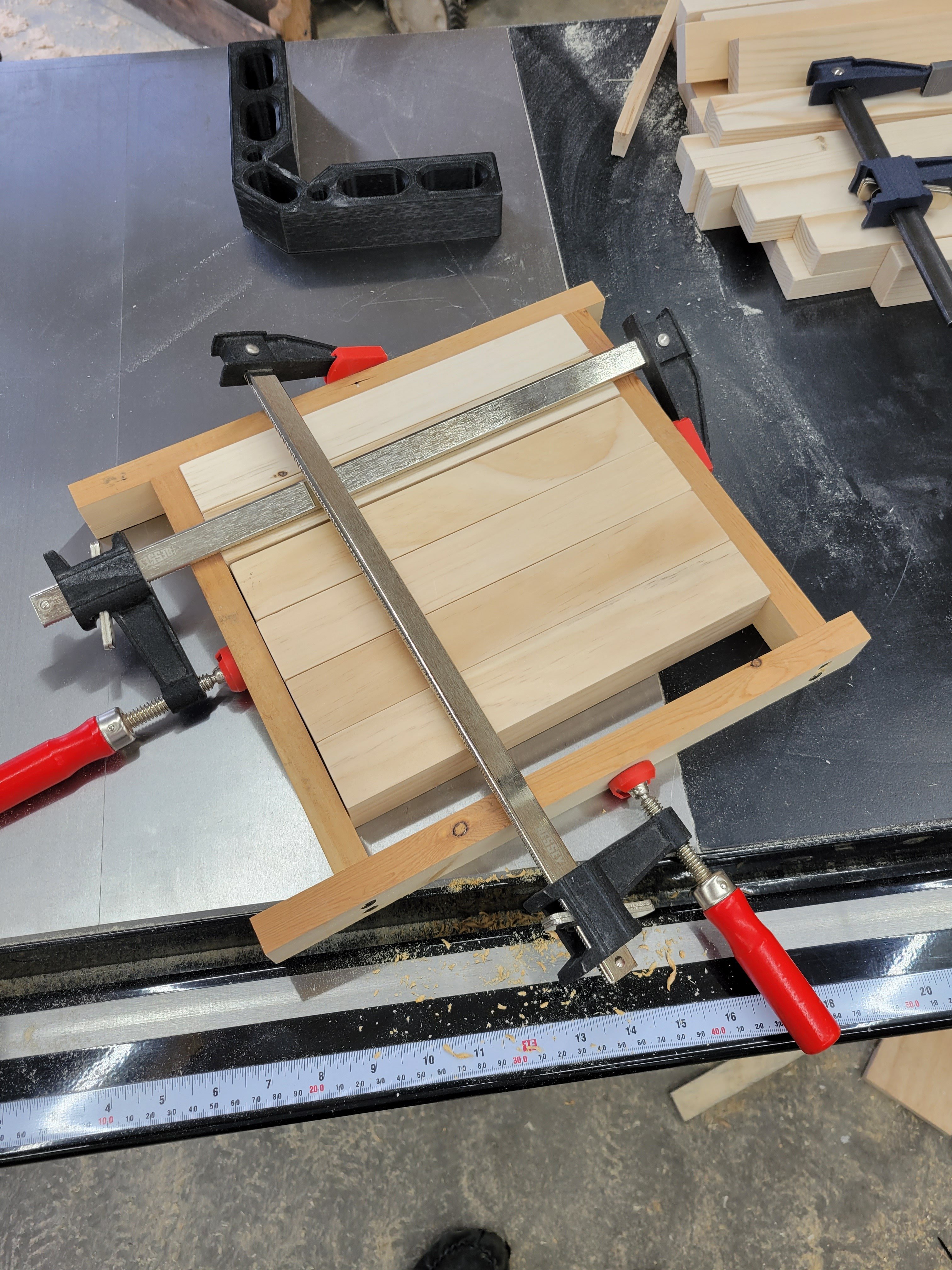

Newb here, I've just finished reading The Essential Woodworker and I'm starting to get into this hobby.

How do those shelves support so much weight?

From what I've been reading it sounds like you need to be very cautious of your joints (at least Essential Woodworker writes that way, based on that I'd have expected you need a tennon through the whole way), but with support on 3 sides those exterior shelves appear to be supporting a lot of weight no problem. Is there somewhere I can learn more about this?

I wish I could give you an academic answer, but I was going off of a similar design and thought if it works there, it should work here.

Honestly I'm a bit worried about the corners, but they feel stable enough.

I used pocket screws and wood glue at each shelf attachment to the frame. The shelf slats are all glued edge grain to edge grain, so in theory the entire shelf should act like a solid board.

I googled and found this post where they tested a similar setup and it failed at 99lbs at 15cm, which looks way way less than the weights you have (plus you’ve got support on two sides, so only like 50% of the load has less support).

I guess the lesson is that the mortise and tenon is very strong, but pocket screws can support a lot of weight too and that’s good enough!

https://woodgears.ca/joint_strength/pockethole.html

Every shelve is a square supported on 3 corners. The weight in the "free" triangle holds because of the opposite corner.

I hope I explain it clear enough.

That makes sense, I’m still trying to understand which joint and why